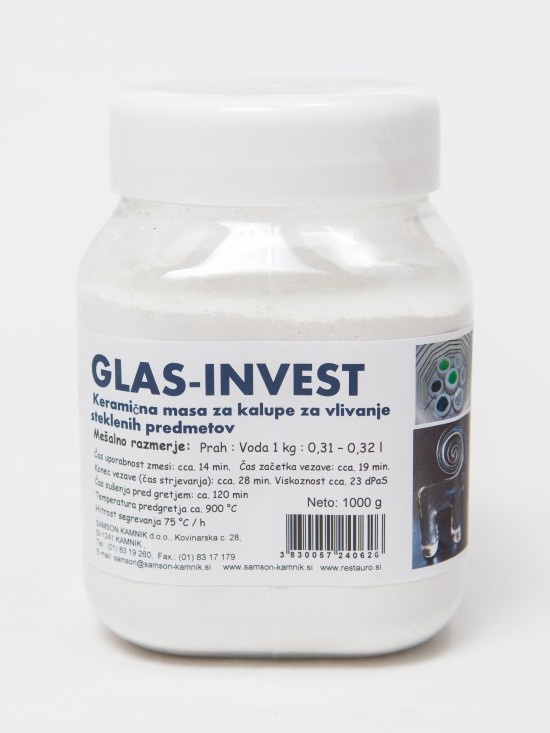

GLASS INVEST for casting glass 1 kg

ADVANTAGES

- smooth surfaces of castings

- fast setting

- easy demolding

Mixing ratio Powder : Water 1 kg : 0.31 – 0.32 l

Usability time of the mixture: approx. 14 min.

Start of binding time: approx. 19 min.

End of binding (setting time): approx. 28 min.

Viscosity approx. 23 dPaS

Drying time before heating: approx. 120 min

Preheating temperature approx. 900 °C

Heating rate 75 °C / h

Usage Instructions

- temper the material and water to 18-22°C

- water temperature above 30°C shortens the setting time, while lower temperatures prolong it

- the mixing ratio can vary according to the complexity of the object's shape within the above-mentioned ratio

- pour the powder into the weighed amount of water, wait for it to soak, and then mix thoroughly; be careful not to incorporate too much air - air bubbles

- if possible, vacuum the mixture, but this is not strictly necessary

- dry at room temperature for at least 120 minutes before heating

- then evaporate the wax – heating for at least 3 hours

- fill the crucible with glass granulate and heat to 900°C

- at a temperature of 200°C, a waiting time of several hours is expected

- heating time at the final temperature is 20-40 hours

- cooling time is approx. 4 days

- waiting time is expected at temperatures of 650 °C and 470 °C

- demolding is performed after cooling to room temperature